MITUTOYO - Linear Height LH-600F/FG | JSR GROUP

High-Accuracy Height Gage Linear Height LH-600F/FG

high-precision 2D linear height gauge for complex work provides high precision up to ± (1.1+0.6L/600) μm

Easy operation using keypad and touch screen navigation, even suitable for beginners

Conduct various measurements such as 2D measurement and perpendicularity measurement with just one tool

Versatile measurements through optional probes

Enhanced data output functions make it easier to manage your measurement data

Easy operation using keypad and touch screen navigation

|

|

Contextual guidance on the large-screen touch panel supports your measurements Simple, straightforward keys with icons Touch panel with guidance Fantastic features for shop-floor use Automatic scale check Calibration reminder Home screen Guidance and measurement navigation Operation log Operation log data is retained for up to 2 months and can be output to a USB memory device. Repeat measurement function To enable efficient measurements, the user can repeat the last measurement with the optional foot switch or on-screen button. |

Various measurements with just one unit

Improved usability and accessibility, including advanced measurement functions

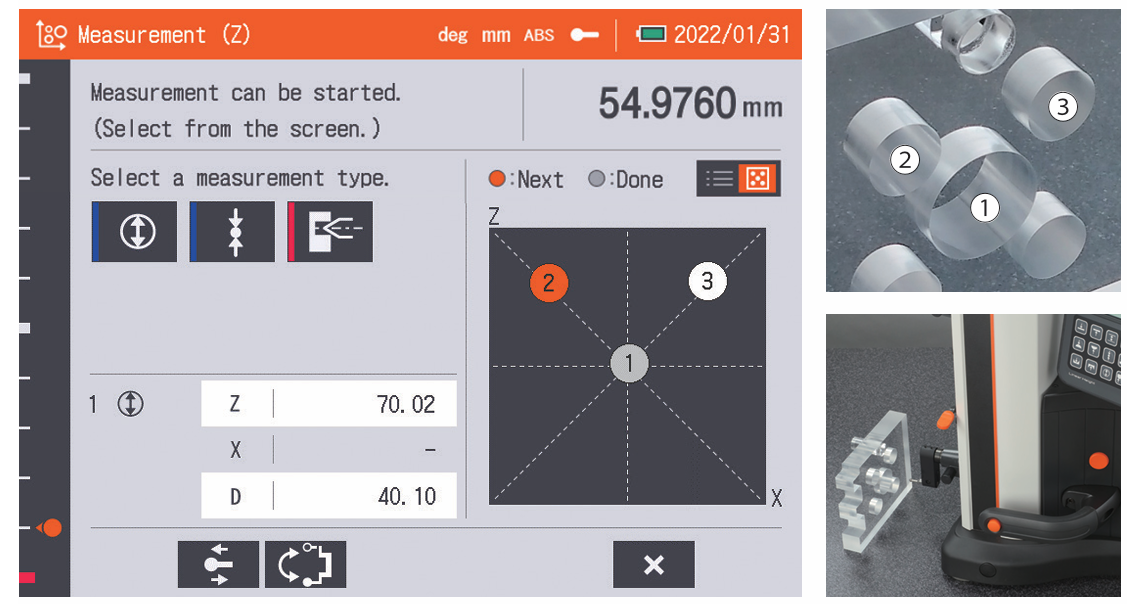

2D measurement - Pre-placement

This function allows the user to register the hole position of the workpiece before measurement.

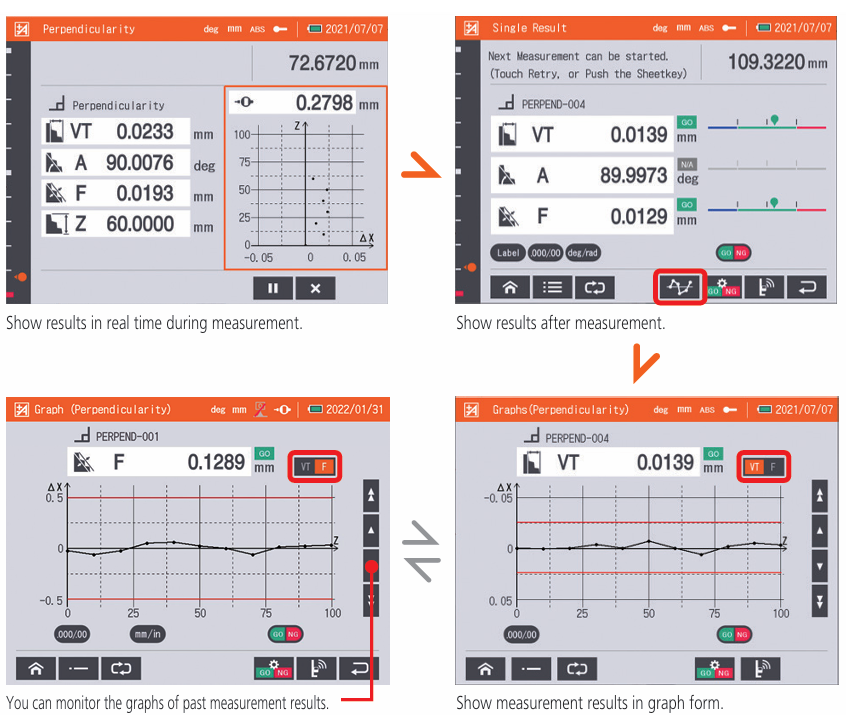

| Perpendicular/straightness measurement- Graph creation You can check the measurement results of perpendicularity and straightness in real time during measurement. After measurement, you can easily see the trends of the measurement results in a graph |

|

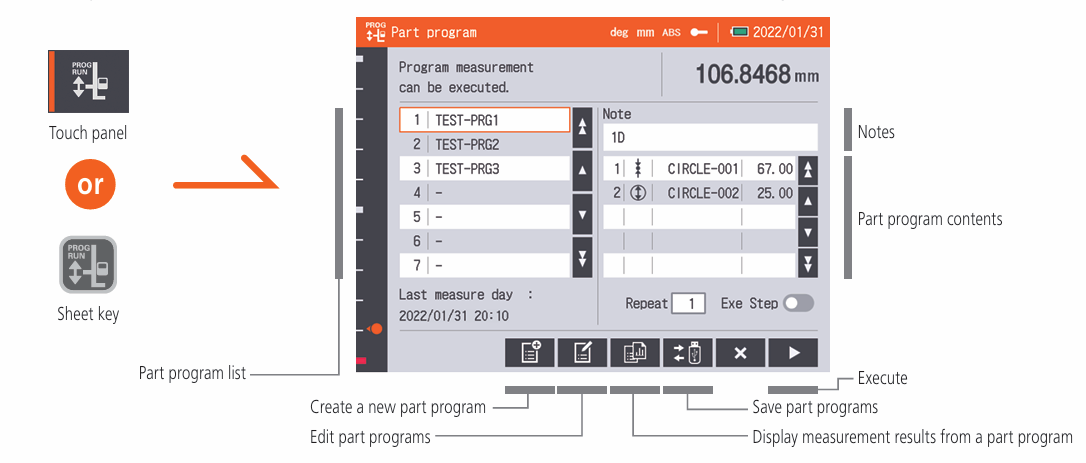

Part program measurement

You can easily access and use the functions of Create, Run, Edit, and View results of part programs.

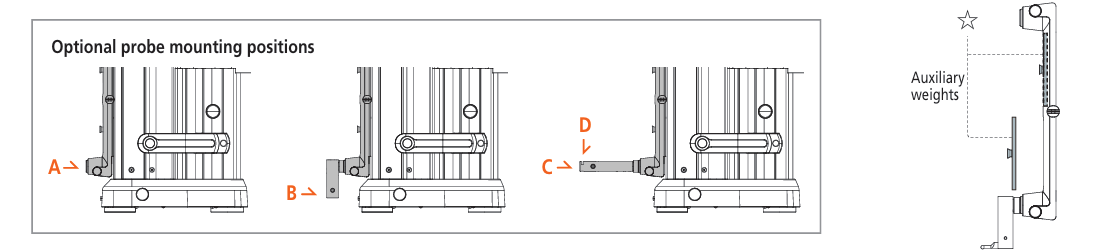

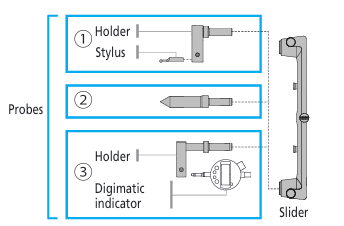

Versatile measurements through optional probes

|

An extension holder and a depth stylus extend the measuring range both horizontally and vertically Three types of optional probes: |

|

|

|

|

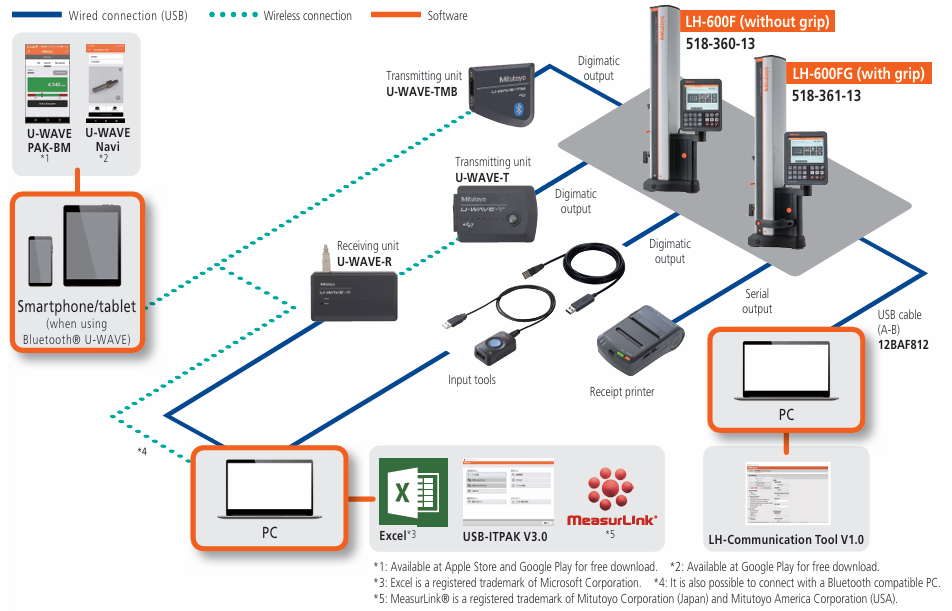

Enhanced data output functions make it easier to manage your measurement data

Data output improves work efficiency and the reliability of recorded data

Specifications

| Model | LH-600F | LH-600FG |

| Order No. inch/mm | 518-360-13 | 518-361-13 |

| Power grip | without power grip | with power grip |

| Measuring range (Stroke) | 0 to 977 mm (600 mm) 0 to 38 in (24 in) | |

| Resolution | 0.0001/ 0.001/ 0.01/ 0.1 mm (selectable)0.000001/ 0.00001/ 0.0001/ 0.001 in (selectable) | |

| Accuracy(at 20 °C) | ||

| Indication accuracy*8 | ± (1.1 + 0.6L / 600) μm, L= Measured length (mm) | |

| Repeatability*8 | Plane: 0.4 μm (2 σ), Hole: 0.9 μm (2 σ) | |

| Perpendicularity(forward and backward)*9 | 5 μm (after compensation) | |

| Straightness(forward and backward)*9 | 4 μm (mechanical accuracy) | |

| Driving method(speed) | Motor-driven (5, 10, 15, 20, 25, 30, 40 mm/s: 7 steps) / Manual | |

| Scale unit | Photoelectric incrermental encoder STVC-20Z | |

| Measuring force | 1 N (automatic constant-force function) | |

| Main unit moving mode | Full-floating (moving) / Semi-floating (measuring) Air bearing (built-in compressor) | |

| Display unit | 8.4 inch touch-screen, LCD | |

| Adjustment of display unit | Stepless tilt adjustment: 0 to 40° Stepless swivel adustment: -30 to 180° | |

| Preventive maintenance | Scale status notification, calibration schedule notification | |

| Probe diameter compensation | Semi-automatic compensation using the probe diameter calibration block (standard accessory) Compensation by inputting the probe diameeter | |

| Power supply | AC adapter 100-240V±10% 50/60Hz/ Battery (NiMH) | |

| Battery operation time*10 | Battery powered(standard): 4 hours, Powered by 2 batteries: 8 hours | |

| Battery charging time*11 | Approx. 3.5 hours (can be used while charging) | |

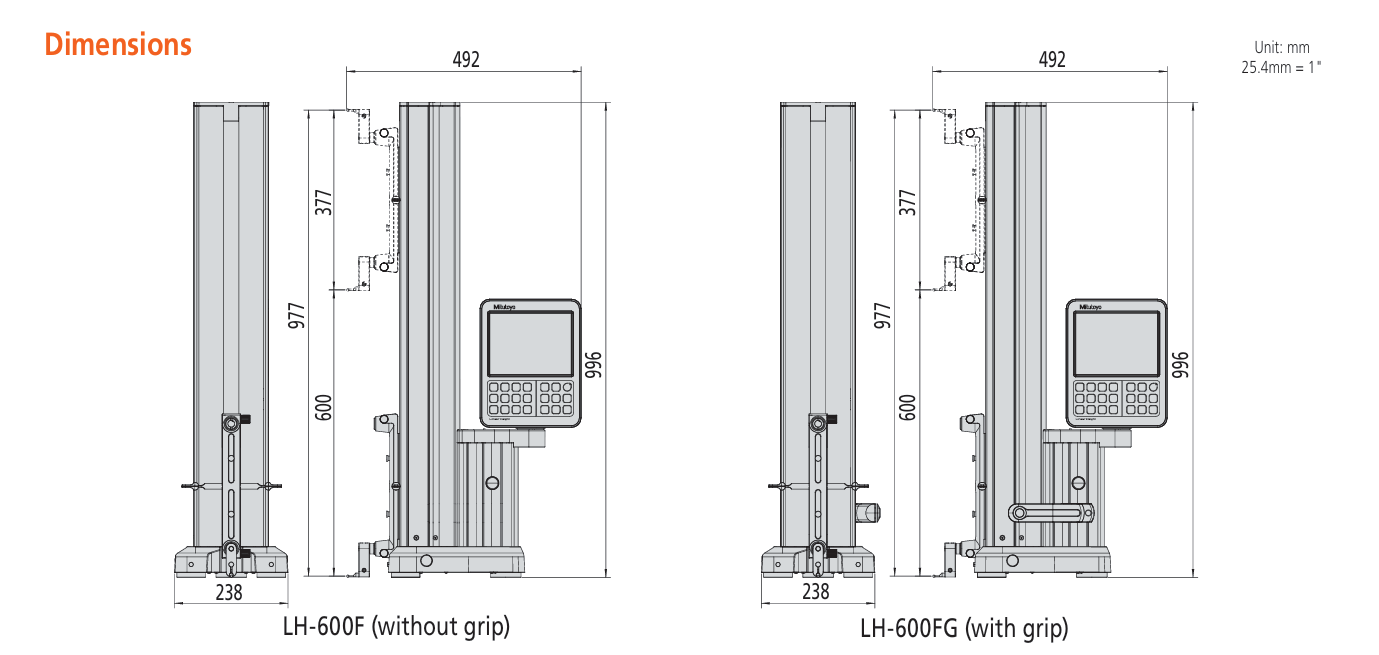

| Dimensions (W×D×H) | 238 (W) × 492 (D) × 996 (H) mm | |

| Mass | 26.1 kg | 26.6 kg | |

| Operating temperature / humidity ranges | 5 to 40 °C/ 20 to 80% RH (non-condensing | |

| Data output | Digimatic d2/ S1 (bi-directional communication) | |